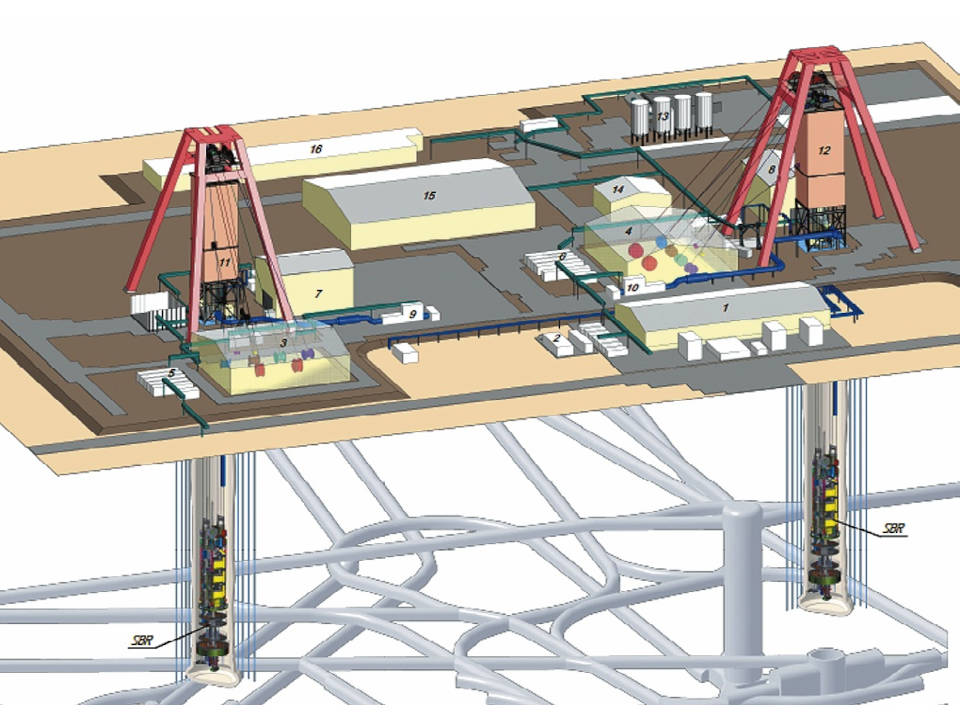

Rapid Mechanized Shaft Sinking

REDPATH DEILMANN GmbH from Germany has been sinking and lining two shafts and initial underground development since 2017 on the territory of the Republic of Belarus (Starobinskoe potassium salt deposit, Luban) by request of Slavkaliy LLC. Shaft sinking is one of the most complicated and time-consuming stages in renovation and construction of new underground mines. In the absolute majority of cases, shaft sinking and lining are at the critical path for implementation of such projects. Rapid rates of shaft construction ensure high technical and economic performance during the commissioning phase and earlier supply of end products to the market. The article introduces an innovative method of mechanized mine shaft sinking that provides rapid parallel sinking and lining of the mine shafts. Unique mechanized shaft boring roadheaders (SBR) manufactured by Herrenknecht are employed. Shaft sinking is done in complicate geotechnical and geological conditions intensified by a very low stability of the rocks using a dedicated rock freezing method. Modern materials are used for additional hydrosealing of the tubing liner. Workings in the near shaft insets are driven with roadheaders. A combination of all these solutions makes it possible to accelerate shaft sinking in a safe way without blasting operations and with high technical and economic performance both for the shaft sinking project and the overall construction of the mining and processing plant.